Ceme-Tube Products and Sales

HDPE Plastic Concrete Forming Tubes

An innovative product that replaces the old-fashioned cardboard forming tube

Products Manufactured In-House in the USA

In-Stock Products Ship Same Day or Next Day

Local In-Store Pickup Available

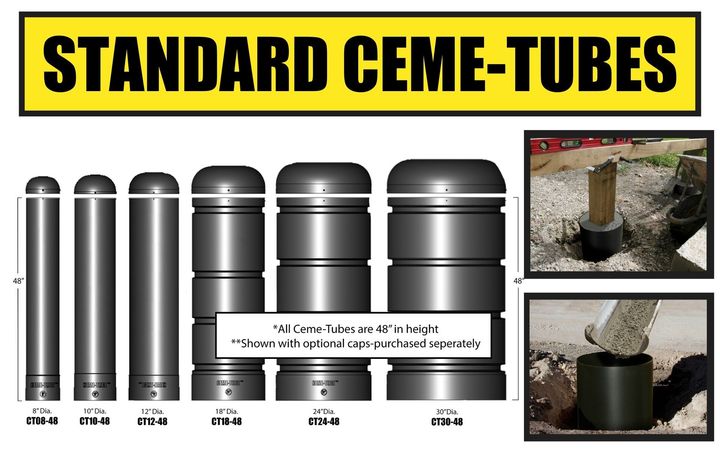

Standard Tubes

Our durable Standard Ceme-Tubes are great for wet locations because they won't fall apart from water exposure, which typically happens with traditional cardboard tubes.

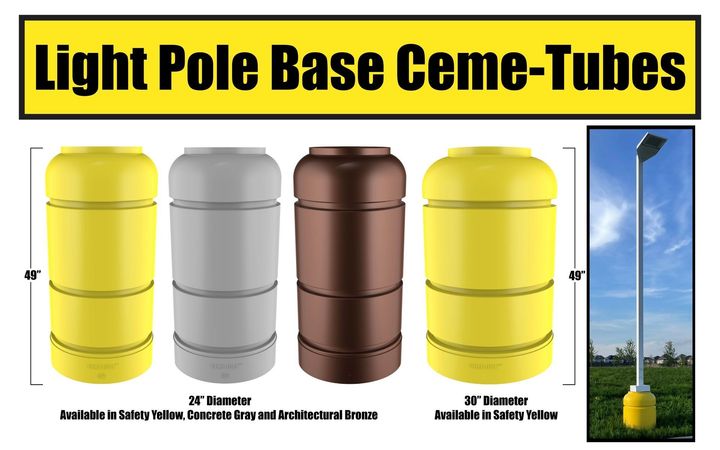

Light Pole Bases

Light pole bases from Ceme-Tube LLC revolutionized the installation of light pole footings because it's finished upon installation and will never need repainting.

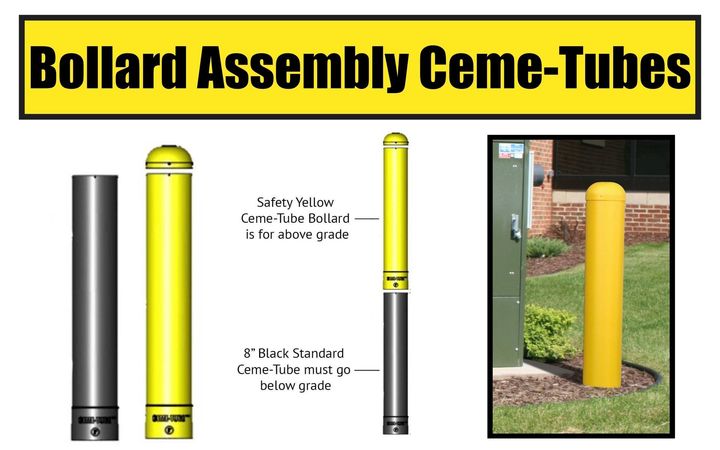

Bollard Assembly

The Bollard Assembly Ceme-Tube is easy to install, maintenance-free, and aesthetically appealing. Neither concrete nor asphalt will adhere to its sides, eliminating any friction from frost heaving.

Quality Products Manufactured in Our Own Facility in Hudson, WI

Established in 2004, Ceme-Tube LLC is a local, family-owned manufacturing facility specializing in the production of high-quality HDPE plastic concrete forming tubes. Our Ceme-Tube products are sold to both individuals and distributors throughout the United States and Canada. We take pride in our products and firmly believe they offer a superior alternative to traditional cardboard-forming tubes.

You can opt to pick up your Standard Ceme-Tube, Light Pole Base Ceme-Tube, or Bollard Assembly Ceme-Tube directly from our Hudson, WI site or have it shipped to you. For in-stock items, we ship out same or next-day on all orders.

Contact us today for any queries or to receive a free quote.

Why Choose Ceme-Tube LLC?

Products Manufactured In-House in the USA

In-Stock Products Ship Within the Same or Next Day

Local In-Store Pickup Available

Over 20 Years of Experience

Family and Locally Owned

Founded in 2004

Here's what our satisfied customers are saying...

At Ceme-Tube LLC, we take pride in providing exceptional Ceme-Tube products to our customers. We would be grateful if you could share your thoughts about our Ceme-Tubes with others. Your feedback helps us improve and helps others make informed decisions. Please take a moment to leave a review of Ceme-Tube LLC and let others know what you think.

Incorporate products into your plans quickly and easily by downloading our design files from CADdetails.com.

The CADdetails program is developed specifically for design professionals with the goal of getting manufacturer-specific product information into their working plans.

CEME-TUBE® is a Registered Trademark of Ceme-Tube® LLC.

Ceme-Tube® products are protected by 2 U.S. Patents:

Patent No. 10,024,018

Patent No. 9,758,942 B2

Ceme-Tube® LLC products are protected by Canadian Patent 2,644,000.

Other patents pending.

serving Area

Nationwide

Canada

and surrounding areas

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Share On: