Standard Ceme-Tubes

HDPE Plastic Concrete Forming Tubes

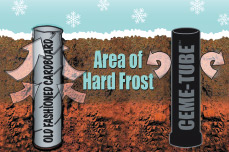

An innovative product that replaces the old-fashioned cardboard forming tube

Products Manufactured In-House in the USA

In-Stock Products Ship Same Day or Next Day

Local In-Store Pickup Available

Standard Ceme-Tube Product Details

Made from partially recycled HDPE plastic and available in 8-, 10-, 12-, 18-, 24-, and 30-inch diameters, Ceme-Tube LLC's new Standard Ceme-Tube™ will change the way footings and piers are made. This revolutionary new product will eliminate many problems with using cardboard forming tubes.

The Ceme-Tube® will not only take job site and shipping abuse, but they can be installed, completely backfilled, and filled with concrete at any future date. All Standard Ceme-Tube® products are four feet in length, but with the integral collar on one end, and can be stacked to produce piers up to 20 feet tall in one pour or 12 feet tall for 30-inch models. The finished pier will be round, smooth, equal in diameter, and of architectural grade for the entire length.

An optional domed cap is available in all sizes to keep rain, dirt, children, and more out of the hole prior to pouring concrete.

Our non-ribbed Standard Ceme-Tubes are available in 8-, 10-, and 12-inch only. Gen 2 Ceme-Tubes with reinforcement ribbing are now available in 18-, 24-, and 30-inch tubes.

Contact Ceme-Tube LLC for more details.

Additional Details

- Impervious to moisture before and after pouring

- Eliminates “friction frost heaving” in colder climates

- Can be installed, completely back-filled, and then filled with concrete at any future date

- Can easily handle job site and shipping abuse without losing integrity

- All models are four feet in length but can be stacked to achieve 20-foot tall piers and footings and can be 12-foot tall for the 30-inch model

- Molded from partially recycled HDPE plastic and is flexible to -103°F

- Will not chip or crack when cold

- Unlike cardboard tubes, the diameters are uniform from one Ceme-Tube® to another

- Easily cut with common power tools

- Can easily be stripped using a grinder with any type of cutting or grinding wheel

- Works well for underwater dock piers

- Will work in conjunction with all manufactured footing bells like Bigfoot

- Optional domed top caps are available for all sizes for prior to pouring

- Finished pier will be round, smooth, and of architectural grade

- No more rotating form lines as with cardboard tubes

- When stripping, only cut the Ceme-Tube® approximately 90% through, score inside cut with a utility knife, and tube will split open with minimal effort

This is a great example of why our HPDE plastic Standard Ceme-Tube is superior to old-fashioned cardboard forming tubes!

These Ceme-Tubes are installed, back-filled, and ready to fill with concrete. There's two feet of standing water inside these Ceme-Tubes, which would make this job impossible with cardboard forming tubes, but not for Ceme-Tubes!

The smooth exterior of our Ceme-Tube in our 8-, 10-, and 12-inch options eliminates friction frost heaving and is impervious to groundwater.

Reviews

Free Product Quotes Within 24 Hours

We ship all in-stock Standard Ceme-Tubes within the same or next day.

(715) 377-2133

Related Products

Incorporate products into your plans quickly and easily by downloading our design files from CADdetails.com.

The CADdetails program is developed specifically for design professionals with the goal of getting manufacturer-specific product information into their working plans.

CEME-TUBE® is a Registered Trademark of Ceme-Tube® LLC.

Ceme-Tube® products are protected by 2 U.S. Patents:

Patent No. 10,024,018

Patent No. 9,758,942 B2

Ceme-Tube® LLC products are protected by Canadian Patent 2,644,000.

Other patents pending.

serving Area

Nationwide

Canada

and surrounding areas

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Share On: